Custom Bubble Mailers

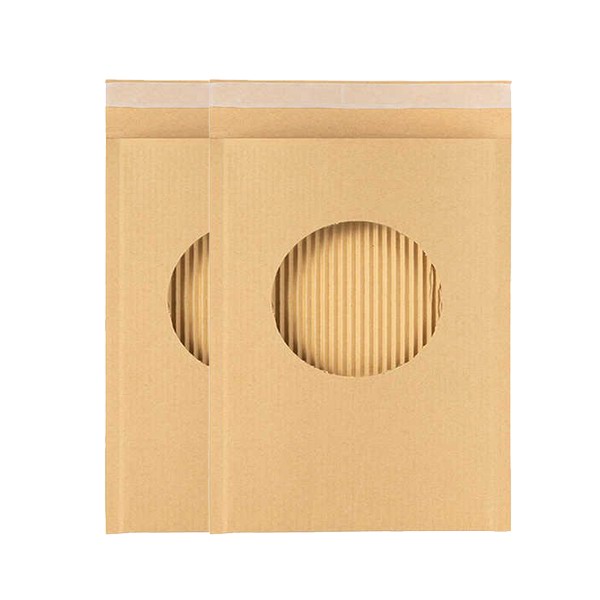

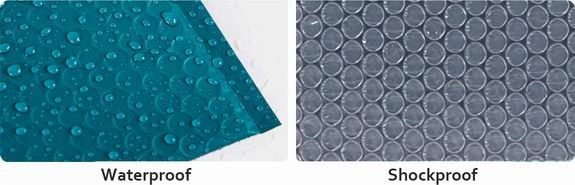

The principle of Bubble mailers is that the film contains air to form bubbles to prevent the product from impacting and ensure that the product is protected when it is shaken. It also has the functions of moisture-proof, heat preservation and heat insulation. It mainly includes kraft paper bubble bags, aluminized Bubble bags, transparent bubble bags and other categories are mostly used in the express delivery industry for the packaging of small-volume, fragile, easily damaged, and precision goods.

1. Products

1.1 Material

LDPE is mainly used as the base material.

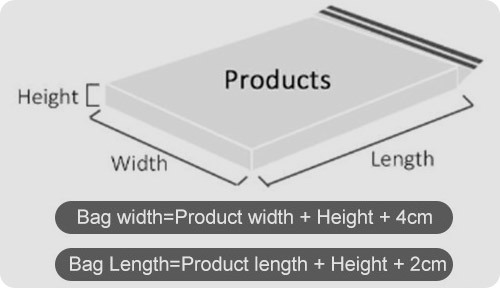

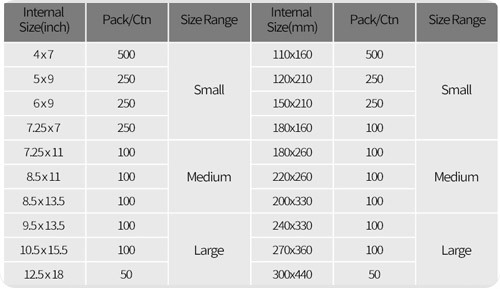

1.2 Size

Bag Width = Product Width + Height + 4cm.

Bag Length = Product Length + Length + 4cm.

1.3 Gram Weight

The weight generally ranges from 200gsm to 700gsm.

1.4 Bubble Size

There are mainly 5mm, 10 mm, 15mm, and 20mm diameter bubbles.

1.5 Glue

The sealing glue mainly uses Henkel Glue.

1.6 Details

The workmanship of express bubble bags is mainly reflected in the smooth and delicate surface of the bubble bag, the integrity of the bubbles, the clear and transparent color, and the good stickiness of the adhesive.

1.6.1 Appearance

Bubble bags are generally made of high-quality PE material, with clear and transparent color and smooth surface. If there is a yellowish or dull color, the bag is likely to be mixed with recycled old materials.

1.6.2 The Feel

High-quality bubble bags are smooth and delicate, with no graininess; while garbage film is unevenly hot-melted due to impure ingredients, and you will feel a slight graininess when you touch it with your fingers.

1.6.3 Workmanship

High-quality cushioning bubble bags are often beautiful in appearance and meticulous in workmanship. On the contrary, if the bags are of inferior quality, they are often of poor workmanship. They usually have problems such as poor sealing adhesiveness, rough texture, and even serious problems such as air leakage.

2. Production Process

The process is sampling, film blowing, lamination, printing, cutting, quality inspection and delivery.

2.1 Sampling

Before mass production, we create a product specification sheet containing the information needed to produce the bubble mailers. After making samples, send them to customers to confirm quality, size, color, drawings and other elements. We only start production after the sample is approved. We can issue a test report if needed.

2.2 Film Blowing

Using a blown film machine, the polymer LLPE particles are extruded into a tubular film blank. The tube film is inflated to the required thickness by high-pressure air under a good melt flow state. After cooling and shaping, it becomes an LLPE film.

2.3 Printing

After the sample is confirmed, we produce the order as per the established specifications and requirements. Currently, we have 60 skilled workers and production equipment including 20 digital printing production lines. Digital printing has the characteristics of saturated printing colors, wide color gamut, and good transition.

2.4 Lamination

Through the all-in-one bubble blowing and laminating machines, we can blow bubbles and laminate at the same time. Coated bubble bags are made by covering the surface of bare bubbles with a layer of other composite materials, such as aluminized film, co-extruded film, pearlescent film, matte film, kraft paper, etc.

2.5 Cutting

The software identifies the graphic outline, automatically generates a cutting path and completes the cutting. Supports setting camera calibration offset compensation, corrects and identifies the overall offset that occurs after the device has been running for a period of time, and ensures accurate graphics cropping.

2.6 Inspection

Quality inspection takes placed in every step of the production process and the most thorough product quality inspection takes placed right before packaging in order to guarantee that no bubble mailers are defective or contaminated. Quality inspections can be arranged with external entities such as SGS or Intertek for external quality inspection.

2.7 Delivery

After manufacturing and packaging the finish product goes to an safe warehouse for storage until they are loaded for transport. We only work with reliable freight forwarders that delivered all cargo on the agreed time and date. Since it’s beginnings that our company has never missed an delivery!