Feather Flag Manufacturer

1. Products

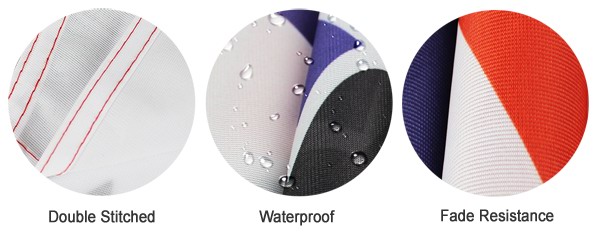

1.1 Fabric

It mainly uses polyester fabric.

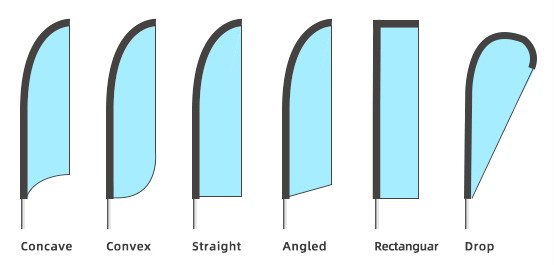

1.2 Pattern

There are six main shapes: concave, convex, straight, angled, rectangle, teardrop.

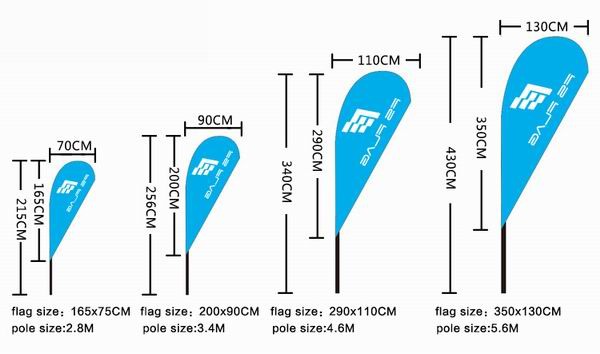

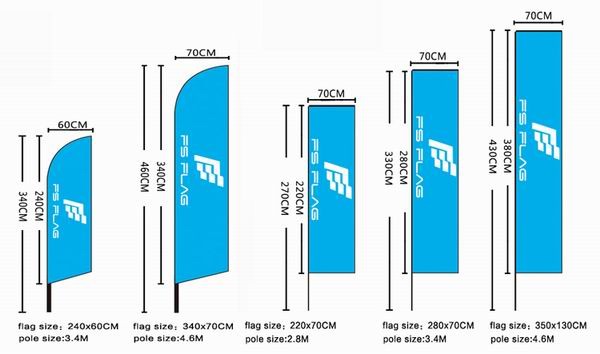

1.3 Size

1.4 Flagpole

It mainly made of all fiberglass material or fiberglass and aluminum material.

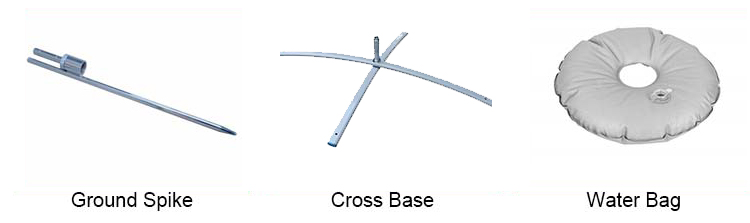

1.5 Base

There are ground spike, cross base, water bag, heavy cross base, wall mount, ect.

1.6 Details

The quality of workmanship of a feather flag is mainly reflected in details such as the color fastness, trimming, stitching and flagpole hardness.

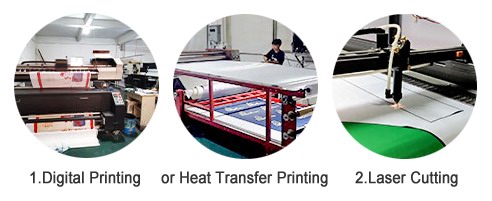

2. Production Process

The process is digital printing or heat transfer printing, laser cutting, sewing, gromment mounting, packaging.

2.1 Printing

After the sample is confirmed, we produce the order as per the established specifications and requirements. Currently, we have 60 skilled workers, and our production equipment includes 20 digital printing production lines, 6 heat transfer printing production lines, as well as laser cutting machines, sewing machines, etc.

2.2 Cutting

Mainly use laser cutting machines. This method uses software to identify the outline of the graphic, automatically generate a cutting path and complete the cutting. Supports setting camera calibration offset compensation, corrects and identifies the overall offset that occurs after the device has been running for a period of time, and ensures accurate graphics cropping.

2.3 Sewing

There are mainly single-needle lockstitch machines, double-needle lockstitch machines and double-needle overlock sewing machines, which have excellent control over processes such as wrinkles, broken needles, misalignment, thread ends, and oil stains.

2.4 Gromment Mounting

The workers install gromment mounts on the corners of the feather flag.

2.5 Packaging

After the feather flags pass a strict quality control process, they can be packaged according to customer specifications. Packaging is as important as the product itself, with all aspects specified and confirmed.