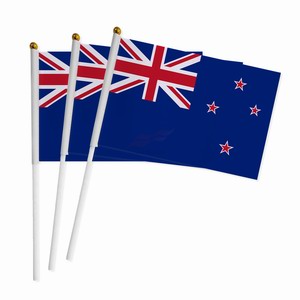

Custom Handheld Flags

We have a strict management system, skilled workers, standard production processes, and stable-running machines, such as digital printing machines, screen printing machines, thermal transfer machines, sewing machines, cutting machines, etc. We produce hand flags according to your needs, using fabrics of different shapes, sizes, materials, and weights, as well as flagpoles of different materials and lengths. In order to produce premium hand flags, we continue to research, continuously improve raw material selection standards and optimize manufacturing processes.

1. Products

1.1 Fabric

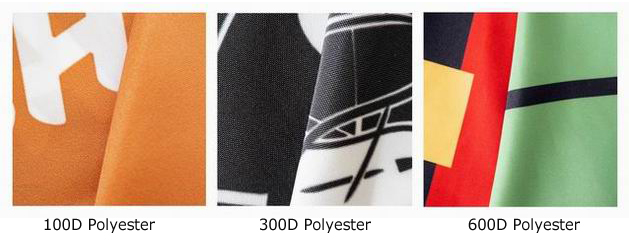

1.1.1 Material

It mainly uses polyester fabric, satin fabric, oxford fabric, etc.

1.1.2 Weight & Flexibility

The weight of fabric: 85gsm, 110gsm, 115gsm, 120gsm, 130gsm, 150gsm, 160gsm, 255gsm and so on.

The flexibility of fabric: 100D, 200D, 600D and so on.

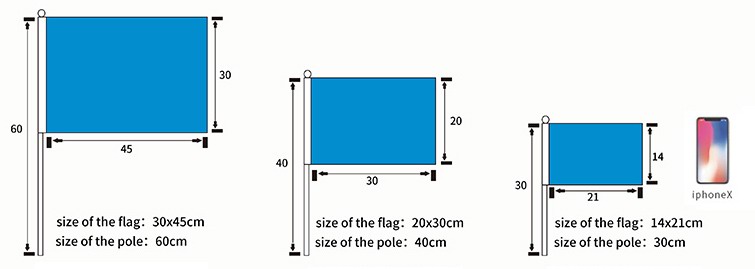

1.2 Dimensions

The aspect ratio is usually 3:2. The common sizes are 10×15cm, 14×21cm, 20×30cm, 30×45cm, 4×6inch, 5×8inch, 6×10inch, etc. 14×21cm and 5×8inch are the most commonly used dimensions.

1.3 Pattern

The hand flags are mainly printed with the patterns of various flags.

1.4 Stitching

There are mainly two ways of wrapping edge with single-needle stitching and double-needle stitching.

1.5 Flagpole

1.5.1 Length

The length of the flagpole is generally twice the width of the flag.

1.5.2 Thickness

Determined according to the size of the flag.

1.5.3 Material

It is mainly made of PVC, PP, wood and other materials.

1.6 Rod Cap

1.6.1 Style

There are mainly two types: conical and spherical.

1.6.2 Material

It mainly uses PVC, PP and other plastics.

1.7 Details

The quality of workmanship of a hand-cranked flag is mainly reflected in details such as the color fastness, trimming, stitching, flagpole hardness and the cap tightness. Common problems of similar products are poor color fastness, Easy burring edge, leaking stitches, easy to break flagpole, loose cap and so on.

After research, the solutions to the above problems are as follows.

1.7.1 Poor Color Fastness

Enhance the color fastness by selecting high-temperature, macromolecular (higher than 350) disperse dyes, as well as effective color-fixing agents and fastness-enhancing agents.

1.7.2 Easy Burring Edge

Laser cutting is mainly used to achieve burr-free cutting. During the hot cutting process, the speed and temperature (approximately between 300-380) should be properly matched, and the cutter should be pressed on the roller with a slight pressure.

1.7.3 Leaking Stitches

Using advanced computerized sewing machines, coupled with sewing workers with more than 10 years of experience and strict quality inspection procedures to eliminate needle leakage.

1.7.4 Flagpole is Easy to Break

The pipe walls of plastic flagpoles such as PVC and PP are thick. And the wooden flagpole is solid.

1.7.5 Pole Cap is not Tight

The molds for the flagpole and pole cap have undergone strict laser distance measurement, and the inner diameter of the cap exactly matches the outer diameter of the flagpole.

2. Production Process

The process is proofing, printing, cutting, sewing, quality inspection, and packaging.

2.1 Sampling

Before mass production, we create a product specification sheet containing the information needed to produce the hand flags. After making samples, send them to customers to confirm quality, size, color, drawings and other elements. We only start production after the sample is approved. We can issue a test report if needed.

2.2 Printing

After the sample is confirmed, we produce the order as per the established specifications and requirements. Currently, we have 60 skilled workers, and our production equipment includes 20 digital printing production lines, 6 screen printing production lines, as well as laser cutting machines, sewing machines, etc.

2.2.1 Digital Printing

It has the characteristics of printing color saturation, wide color gamut, good transition, double transmission effect, the same softness as the flag surface, immersion and sunlight and so on.

2.2.2 Silk Screen Printing

It is suitable for 1-4 different color compositions and simple pattern printing with transitional colors. It has the characteristics of strong adhesion and the printed pattern is more three-dimensional.

2.3 Cutting

It mainly uses laser cutting machines. This method uses software to identify the outline of the graphic, automatically generate a cutting path and complete the cutting. It supports setting camera calibration offset compensation, corrects and identifies the overall offset that occurs after the device has been running for a period of time, and ensures accurate graphics cropping.

2.4 Sewing

There are mainly single-needle lockstitch machines, double-needle lockstitch machines and double-needle overlock sewing machines, which have excellent control over processes such as wrinkles, broken needles, misalignment, thread ends, and oil stains.

2.5 Inspection

It mainly includes quality inspection procedures such as color fastness, flagpole hardness and stitching. The Color Fastness mainly includes water fastness, dry rubbing fastness and acid-alkali perspiration fastness.

2.6 Packaging

Mainly using relatively independent packaging, such as 30 flags in one packaging bag and 30 flagpoles in another packaging bag, placed in the same packaging box. The specific quantity allocation method can be determined according to customized requirements.

Connect With Us Today!

Let Fulfill Packaging be your partner in delivering high-quality hand flags. Contact us for samples, quotes, and to learn how we can help grow your product line with our exceptional products.